Widely used in thermal power, steel, coking, sintering, ceramics, glass, cement, chemical and other fields. After long-term successful proved operation, it has high efficiency of deNOx and long service life.

![]()

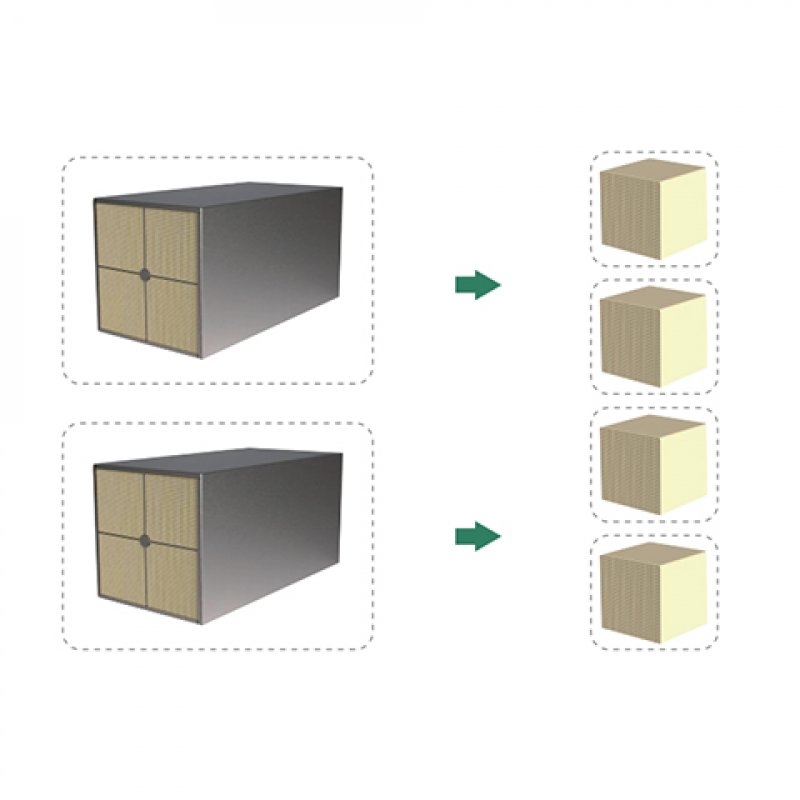

The perfect combination of technology and craftsmanship

Industry-leading ultra-low temperature and high-temperature technology

Use temperature 150-180 ℃, high efficiency, high water resistance (25%), high mechanical strength, wear resistance, alkali resistance, can be heated online regeneration.

Use temperature 280-420 ℃, high-quality raw materials, high efficiency, low ammonia escape, high mechanical strength, high wear resistance, dioxin and mercury removal

Use temperature 180-280 ℃, high efficiency, high water resistance, high sulfur resistance, high mechanical strength, wear resistance, alkali resistance, can remove dioxin

The operating temperature is 420-600 ℃, and the cordierite-coated copper-based molecular sieve has high efficiency, small volume, high temperature resistance, high mechanical strength, and wear resistance.

The ultra-low temperature denitrification catalyst developed by the company has good denitrification performance under low sulfur and dust conditions at 150-180°C in the ultra-low temperature section. The denitrification efficiency can reach more than 90%. It is widely used in Vaiours industries such as natural gas boilers and kilns.

The company's self-developed low-temperature deNOx catalyst adopts advanced production technology. The catalyst has very good deNOx performance in the low temperature section (180-280 °C), it can process high concentration of nitrogen oxides, and the deNOx efficiency is over 95%. Low-temperature deNOx catalysts are widely used in coking plants, sintering machines, small industrial boilers, industrial furnaces, glass and other industries.

This type adopts a front-end hardening process, increase the wear-resistant coating and maintain a long mechanical life. The raw material is made of high quality anatase titanium dioxide with large specific surface area. It is optimized for the flue gas environment of various industries and has strong anti-poisoning ability. The product design can be carried out for different flue gas conditions, with strong pertinence and excellent product performance. Widely used in power plant boilers, industrial boilers and other industries, to adapt to temperature range of 280-420°C.

This type adopts international advanced technology and high-quality cordierite catalyst carrier. Coating composite molecular sieve catalyst, to improve the activity and stability of the catalyst at high temperature. It can be widely used in 300-550°C working conditions, and can be customized according to different industry conditions. It is commonly used in various high-temperature flue gas fields such as gas kiln and diesel engine.

The dioxin-catalyzed oxidative deNOx double-effect catalyst developed for the waste-to-energy and waste incineration industry has the double functions of denitrification and de-dioxin, and the deNOx efficiency can reach over 90%. The catalyst is formulated with a specific performance and excellent performance.

The deNOx catalyst developed for the coking industry is suitable for temperature range (170-300 °C), and it has strong sulfur resistance, the deNOx efficiency can be over 95%. This type is very mature with large amount of application cases, which can effectively deal with the coking industry flue gas.

The deNOx catalyst developed for the sintering machine is suitable for temperature range(170-300°C), the catalyst can be customized according to different deNOx processes. The deNOx efficiency can reach more than 95%, and it also has dioxin function. After the post-deNOx process, the catalyst activity is stable and maintain a long service life.

The gas-fired boiler SCR deNOx catalyst has the characteristics of small volume, strong temperature adaptability and high deNOx efficiency, and it is widely used in various types of gas boilers.

The deNOx catalyst developed for the sintering machine is suitable for temperature range(170-300°C), the catalyst can be customized according to different deNOx processes. The deNOx efficiency can reach more than 95%, and it also has dioxin function. After the post-deNOx process, the catalyst activity is stable and maintain a long service life.

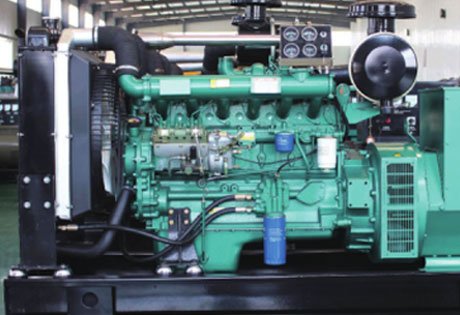

For the diesel generator set, we developed molecular sieve high-temperature catalyst, which can meet the special working conditions of the unit and meet the national five emission standards. It has the characteristics of small volume, high temperature resistance and wear resistance. The maximum application temperature is 550°C and the deNOx efficiency is over 95%.

For various types of ships, 300-420°C section and 420-550°C section deNOx catalysts are developed to meet all types of engines and generator sets. Small and compact volume, high strength and wearability, it can also meet international and domestic emission standards.

If you have any questions or needs about the product, please fill in the following form and we will contact you as soon as possible.